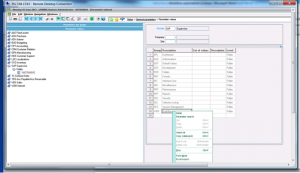

Sage ERP X3 Toronto Area Consultant Tip: 6 Steps to Email Reports

Sage ERP X3 Toronto, CN Consultant Question: How do I email reports, purchase orders, sales orders, receipts, or invoices? As a Sage ERP X3 Toronto-...

1 min read

Ken Jacobsen Wed, Sep 25, 2013

Sage ERP X3 offers a scalable solution that can grow with your business. One of the Sage ERP X3 features that users love most is the role-based menu system that provides information specific to the user and graphical workflows to support business procedures. As full-featured as Sage ERP X3 is for formula-based manufacturers, many companies still end up having to manage some functions such as lab testing and result tracking in Microsoft Excel. However, you can automate this process and also meet the new GHS regulatory requirements for SDS forms and container labels with Formulator™, which integrates with Sage ERP X3 and several other ERP applications.

Sage ERP X3 offers a scalable solution that can grow with your business. One of the Sage ERP X3 features that users love most is the role-based menu system that provides information specific to the user and graphical workflows to support business procedures. As full-featured as Sage ERP X3 is for formula-based manufacturers, many companies still end up having to manage some functions such as lab testing and result tracking in Microsoft Excel. However, you can automate this process and also meet the new GHS regulatory requirements for SDS forms and container labels with Formulator™, which integrates with Sage ERP X3 and several other ERP applications.

Sage ERP X3 Toronto, CN Consultant Question: How do I email reports, purchase orders, sales orders, receipts, or invoices? As a Sage ERP X3 Toronto-...

1 min read

Why Do Sage 100 and Sage X3 Customers Need Trade Promotion Management Integration? As Sage 100 and Sage X3 consultants, we help our clients with many...

1 min read

As a Sage ERP X3 consultant, we have many clients who outgrow QuickBooks and choose to migrate to Sage ERP X3. So when Sage ERP X3 jumps in the ring...