What's The Value of Competitive Lean Manufacturing Strategies?

Lean manufacturing strategies have been a goal of most companies over the last few years. Why is Lean so popular? Lean delivers what companies...

2 min read

Greg Miles Fri, Mar 28, 2014

One huge benefit to implementing a warehouse management system or WMS software is removing the manual tracking of the picking process in the warehouse. Warehouse that move from a paper picking process to a wireless device to pick and pack and ship more efficiently and productively. Warehouses come in different shapes and sizes. Some are “wide open” in a square shaped space. Others are contained in buildings on multiple floors, utilizing elevators to transport materials. Warehouses will have varying ceiling heights. Some might have yard space. Materials handling will differ by product shape and size. As a result, racking infrastructure will vary by product size. Many warehouses keep large products in bulk stacks or pallet racks. While with small products, picking efficiency may be increased by storing smaller products in flow racking or static shelving.

One huge benefit to implementing a warehouse management system or WMS software is removing the manual tracking of the picking process in the warehouse. Warehouse that move from a paper picking process to a wireless device to pick and pack and ship more efficiently and productively. Warehouses come in different shapes and sizes. Some are “wide open” in a square shaped space. Others are contained in buildings on multiple floors, utilizing elevators to transport materials. Warehouses will have varying ceiling heights. Some might have yard space. Materials handling will differ by product shape and size. As a result, racking infrastructure will vary by product size. Many warehouses keep large products in bulk stacks or pallet racks. While with small products, picking efficiency may be increased by storing smaller products in flow racking or static shelving.

Adding to the complexity, product velocity and order types also affect warehouse layout and consequently the picking strategies. Companies that ship single-sku pallets of product to customers will have significantly different warehouse operations than ones that ship trailer loads of mixed-sku pallets (grocery is a good example of this).

Even subtle differences in customer requirements for consumer products wholesalers will have substantial effects on the materials handling and picking. Operations that ship to retail distribution centers will have different fulfillment requirements than those that ship directly to stores.

Accellos One Warehouse has an abundance of picking styles that will accommodate a warehouse manager’s fulfillment strategy independent of warehouse layout, product size, velocity and order characteristics. These different picking styles are designed to boost picking accuracy in the warehouse; up to 99.9%!

Some of the many picking styles are listed below:

• Wave Picking

• Batch Picking

• Product Picking

• One Scan Picking

• Scanner Picking

In addition to picking styles, there are numerous benefits for having warehouse picking systems including:

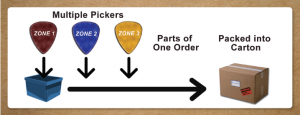

• Multiple pickers can pick in a single sales order

• Single picker can pick on multiple sales orders

• Password protection for skipping and shorting picks

• Configurable worklow prompts for bin, packsize, and carton

• Ability to generate a packing slip after last pick

• Ability to assign orders to s specific user

• Ability to repack item

• End of Line (EOL) workflow controls what additional processes happen to sales orders after they are fully picked

• And more, including additional advanced picking functionality

Next Steps:

• Visit our Warehouse Management Systems Page

• Request a Free WMS Demo Here

• Receive a “Ballpark” Estimate Here

• Be Sociable, Share!

If you have additional questions about WMS software solutions or any other questions about this blog, please contact us here or you can call 717.704.1000 ext.3010. You can also email us at info@icepts.com. Since 1980, iCepts Technology Group has been offering the “Best-of-Class” technology solutions to help companies streamline their specialized business departments and become more efficient and therefore profitable. Our WMS and ERP consultants have implemented hundreds of systems throughout the Mid-Atlantic Region spanning from Ohio, Pennsylvania, New York, New Jersey and Virginia. We can help your company determine the appropriate technology fit. Discover why customers have been with iCepts for so long; our vast industry knowledge, friendly personnel and superior customer service!

As experienced SCM, WMS and ERP consultants and value added resellers (VARs), we provide start to finish services for the solutions we represent Microsoft Dynamics NAV for Distribution and Manufacturing, Accellos Warehouse Management System (WMS), Server virtualization, open source VOIP phone systems and infrastructure and security. We provide services that cover process analysis, implementation, training, security and networking. Naturally, we also provide full ongoing support for years after implementation to help our clients succeed. We are your one stop shop for your business technology needs.

Photo courtesy of www.freedigitalphotos.net

A version of this blog was previously posted on iCepts’ website :net

Lean manufacturing strategies have been a goal of most companies over the last few years. Why is Lean so popular? Lean delivers what companies...

Warehouse Management Systems (WMS) – Two Types of Zone Picking and the Basics Today’s distribution centers (DC) understand the importance of...