Wave Picking and Warehouse Management System (WMS) Basics

The Basics of Wave Picking and Warehouse Management Systems (WMS) Every distribution company knows the importance of operational efficiency when it...

Today’s distribution centers (DC) understand the importance of maintaining accuracy while working to increase productivity Keeping up with this fulfillment challenges are two reliable constants. . As the Amazon affect begins to make just about every company a multi-channel fulfillment company, knowing if you are picking the right order or, more importantly, picking the order in the right way becomes an important determinant in the overall productivity of your operations. Welcome to our series of blogs where we cover different picking methods and warehouse management systems (WMS) basic principles. In our previous warehouse management posts, we explored batch picking, wave picking and the basics of discrete picking. In this blog, we will review the basics of zone picking as it relates to the assembly line part of the warehouse operations.

Zone Picking is the order picking version of the assembly line. In Zone Picking, the picking area is broken up into individual pick zones. Order pickers are assigned a specific zone, and only pick items within that zone. This method divides up aisles of bins so that individual pickers only work in a specified number of aisles. In Zone Picking it’s important to balance the number of picks from zone to zone to maintain a consistent flow.

Zones are usually sized to accommodate enough picks for one or two order pickers. Creating fast pick areas close to the conveyor is essential in achieving high productivity in zone picking. Zone Picking is most effective in large operations with high total numbers of SKUs, high total numbers of orders, and low to moderate picks per order. Separate zones also provide for specialization of picking techniques such as having automated material handling systems in one zone and manual handling in the next.

Depending on your warehouse and assembly line layout and setup, Zone Picking can be done the following ways:

Here's what this looks like:

One picker picks all the products in one area of the warehouse. Orders are moved from one zone to the next as the picking from the previous zone is completed. Conveyor systems can used to move orders from zone to zone or, in a more manual process, the picker hands off the rest of the wave to the next picker in another area of the warehouse.

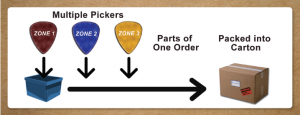

With Simultaneous Zone Pick, pickers in different areas (zones) of the warehouse work on the same order at the same time. The cartons are then consolidated and/or re-packed downstream when zones have been completed. Simultaneous Zone Picking can prevent the problem of slowdowns in picking because of hold-ups in a particular area or due to a bottle neck in the packing.

The goal of zone picking is to create greater speed in the picking process. Zone picking also allows specialization based on skill level. For example, fork truck operators can be assigned to a zone that exclusively houses large items that must be picked with a lift. Zone picking also has a potential positive effect on employee morale by having pickers take pride and ownership in their area and can result in less operator fatigue and the end of shifts due to reduced travel distances.

Keep pickers picking…not waiting…Keep a queue of orders and/or products available to the picker. This requires an effective replenishment strategy if you are using a forward pick/reserve storage layout.

Keep pickers picking…and not doing non-pick tasks…Do not bog pickers down with other tasks such as carton erection and taping, labeling, wrapping, adding dunnage, etc. Pickers are typically your most skilled warehouse resource.

Minimize product touches…Ideally, it is best to design your pick process so that there is sufficient accuracy at the time of picking to eliminate the need for subsequent checking and repacking. Each unit of product is touched only by the pickers’ hands before the carton is sealed and transported to an outbound truck.

Minimize travel…Pick from both sides of the aisle from properly sized pick modules. Unused space between pick modules and pick lanes can unnecessarily lengthen a pick path. Segregate slow movers from fast moving SKUs to avoid repetitive, unproductive travel past them when not needed.

Consider picking very slow moving SKUs from reserve storage rather than forward pick bins. Seek opportunities to batch pick many smaller orders in one trip. Pick all one-line, single-piece orders together since no sorting is necessary to break them down into a discrete order level.

Learn more about Warehouse Management Systems (WMS)

Posted by iCepts Technology Group, Inc. An Accelos and Microsoft Dynamics NAV Partner in Pennsylvania

We are a Microsoft Dynamics NAV Partner offering implementation, service, and support for Microsoft Dynamics NAV in: PA, DC, DE, MD, NC, NJ, NY, OH, VA, WV, and the entire Mid-Atlantic Region. We also offer implementation, service, and support for Accellos One Warehouse Management Systems in: PA, DC, DE, MD, NC, NJ, NY, OH, VA, WV, and the entire Mid-Atlantic Region.

As experienced SCM, WMS and ERP consultants and value added resellers (VARs), we provide start to finish services for the solutions we represent Microsoft Dynamics NAV for Distribution and Manufacturing, Accellos Warehouse Management System (WMS), Server virtualization, open source VOIP phone systems and infrastructure and security. We provide services that cover process analysis, implementation, training, security and networking. Naturally, we also provide full ongoing support for years after implementation to help our clients succeed. We are your one stop shop for your business technology needs.

Contact us for additional information by clicking HERE or...

Phone: 717.704.1000

Email: info@icepts.com

Another version of this article was previously posted by iCepts Technology Group, Inc.- A Pennsylvania Microsoft Dynamics NAV Reseller on Sept. 6, 2016 -

http://www.icepts.com/warehouse-management-basics-zone-picking/

The Basics of Wave Picking and Warehouse Management Systems (WMS) Every distribution company knows the importance of operational efficiency when it...

Batch Picking and Warehouse Management Systems (WMS) Growing distribution centers (DCs) are well aware of the two constant challenges to achieve both...

Discrete Picking and Your Warehouse Management System (WMS) As your business grows, maintaining productivity while also keeping accurate inventory...