Getting Started On A 5S implementation, pt. 3

This is our third and final installment of our series on 5S implementation. If you haven't already, take the time to read it from the beginning...

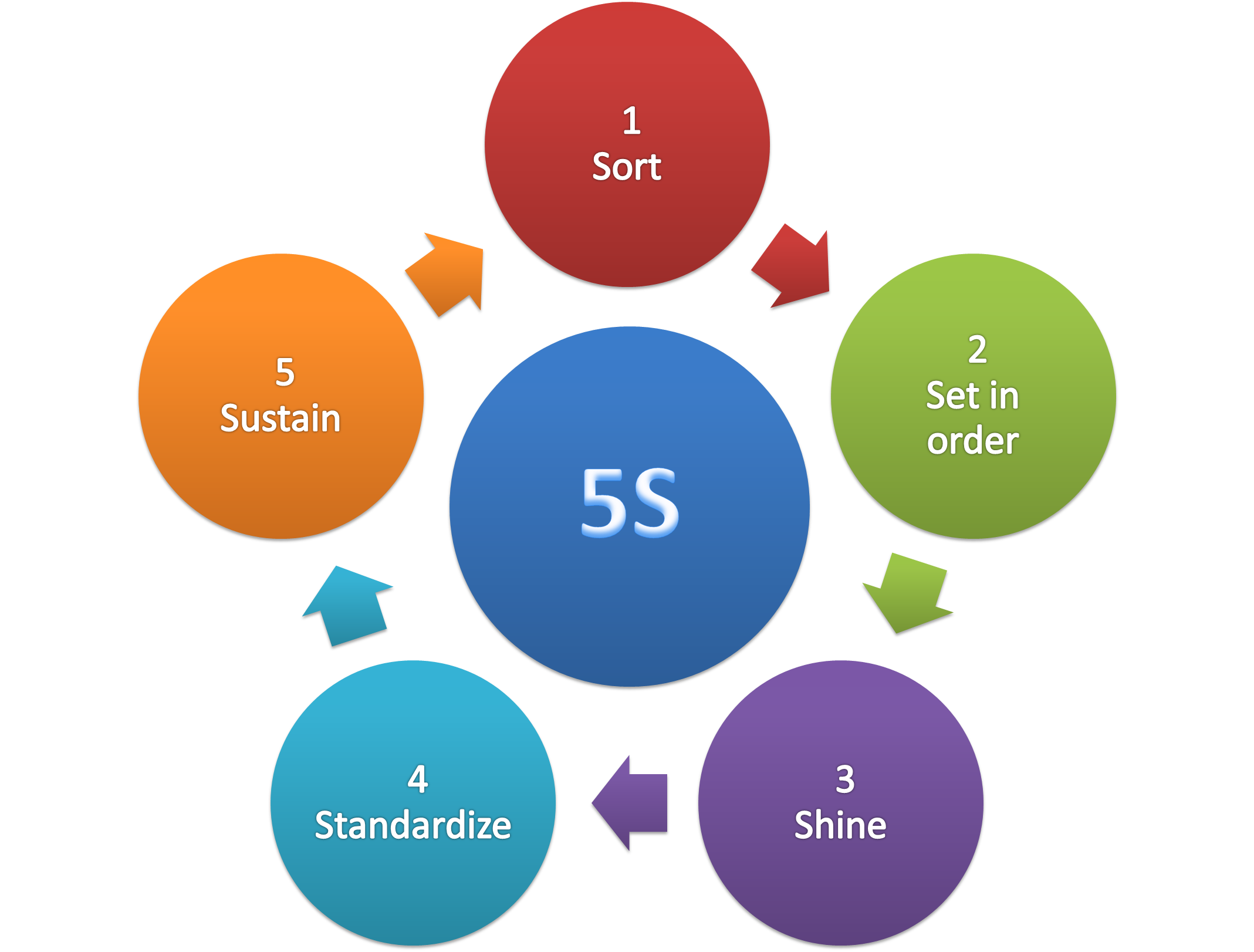

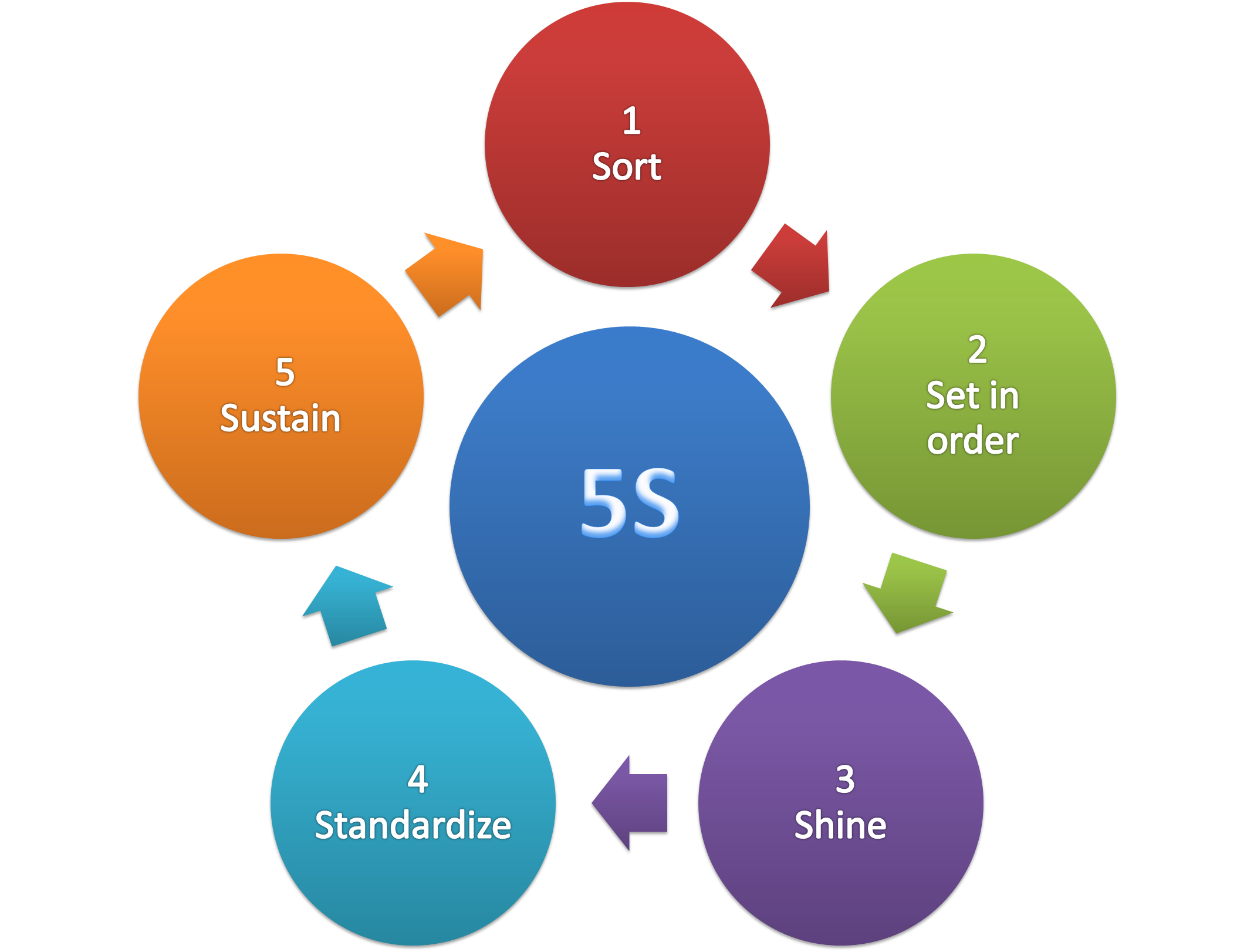

This is part 2 of our series on 5S implementation. In part one, we talked about getting everyone on the same page about the implementation alongside setting goals and expectations in the implementation of 5S. This article will discuss 2 tips that will help ensure a fast and successful implementation.

With all the changes your employees will have to make it’s important that you do your part to make the implementation process as simple as possible. This includes preparing laborers with training, providing materials, and guidelines. Doing this will show your support of your employees efforts and that their work won’t go unnoticed.

Provide All Needed Materials- A simple way to show your support of your employee’s efforts before the implementation is by giving them a 5S starter pack. On top of it being a helpful gesture, it will also be useful in making the implementation go faster since they won’t have to spend time looking around for materials to use for the 5S process. If you don’t have time to put starter kits together, then you can always purchase them pre-packaged.

Make it easy to give needless items away- If applicable, it is a good idea to put someone in charge of the disposal of your unwanted or unused items. This will support your employees by letting them focus on more important task of organizing the warehouse and/or facility. If you can’t assign someone to be in charge of disposal, then it is recommended that you find a charity organization that can reuse or otherwise dispose of the items for you like Habitat for Humanities restore.

Set the standards- Make it easy on your team and let the experts with the greatest company knowledge set the standards for your 5S system. This will make the process go faster because your employees will know exactly what is expected of them as well as what is needed from their implementation efforts. It is also a good idea to distribute your standards in a handout or hang posters that are easily referenceable.

If you’re a company with a lot of facets or facilities, approaching the launch of an implementation can feel like a citywide clean up rather than a simple spring cleaning job. You can make it easier and less overwhelming on your personnel by creating systems to get the work done.

Break it up- In some instances, it is best to work together on one big task. That is not the case with implementing 5S; the smaller you can break up tasks the better your results will be. It is especially true if your team has a lot of ground to cover. First you will want to break employees into groups for each area of the facility(s) with an appointed leader. Then each group should appoint sub-groups to be in charge of each part of the implementation. For example, one sub-group should oversee sorting, another sub-group in charge of the general cleaning of the area, etc.

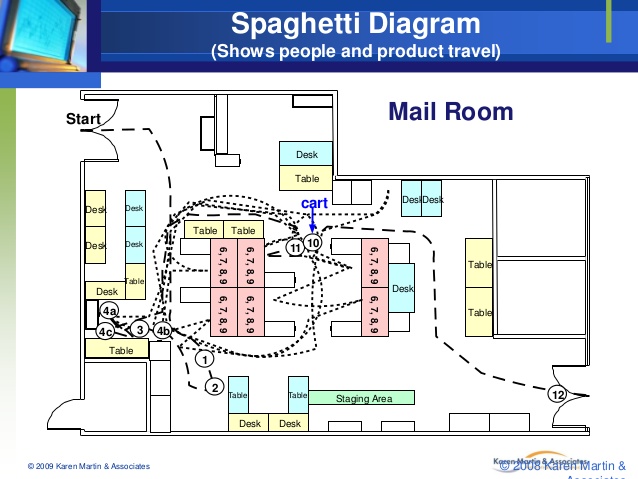

Test your efficiency- When setting your facility in order (the second step in 5S) you should take the opportunity to evaluate your operations. Approach in the same way you would approach a lean manufacturing implementation in that you should be looking for patterns of work behavior and efficiency. You can do this by making a chart of the facility and tracking the path your people should take to complete their tasks for the implementation (see example chart below). By doing this you will be able to see what parts of your company’s operations are going great and what needs improvement.

Set up Shine Stations- To make the “Shine” step go faster and more convenient it is ideal to provide nearby shine stations with supplies for surface cleaning, dusting, sweeping, etc. As a general rule of thumb, if it takes your personnel longer than 15 seconds to walk to the station it is too far. A good way to prevent this to make your “Shine” stations mobile. Perhaps even use a cart for your station for easy access and transportation between work areas.

Stay tuned for more tips and best practices for implementing 5S in the upcoming weeks.

Clients First is an expert at implementing Acumatica, Dynamics 365 and Dynamics AX (which also made it into the leader quadrant). Contact our sales team today by calling 800.331.8382. Clients First implements and supports clients across the U.S.A. and in 11 countries. Our team of professionals are ready to help implement the best finance and operations solutions for manufacturers, distributors, project-based manufacturers, MRO (maintenance, repair and overhaul), and professional services.

Source: Industry Week

This is our third and final installment of our series on 5S implementation. If you haven't already, take the time to read it from the beginning...

Do you know the real reasons why ERP implementation fails so often? Typically, a successful ERP implementation requires not only a large capital...

1 min read

Why is a Post-ERP Implementation Strategy Important? At Mantralogix, our ERP consultants spend a lot of time discussing ERP implementation...