Getting Started On A 5S Implementation, pt. 2

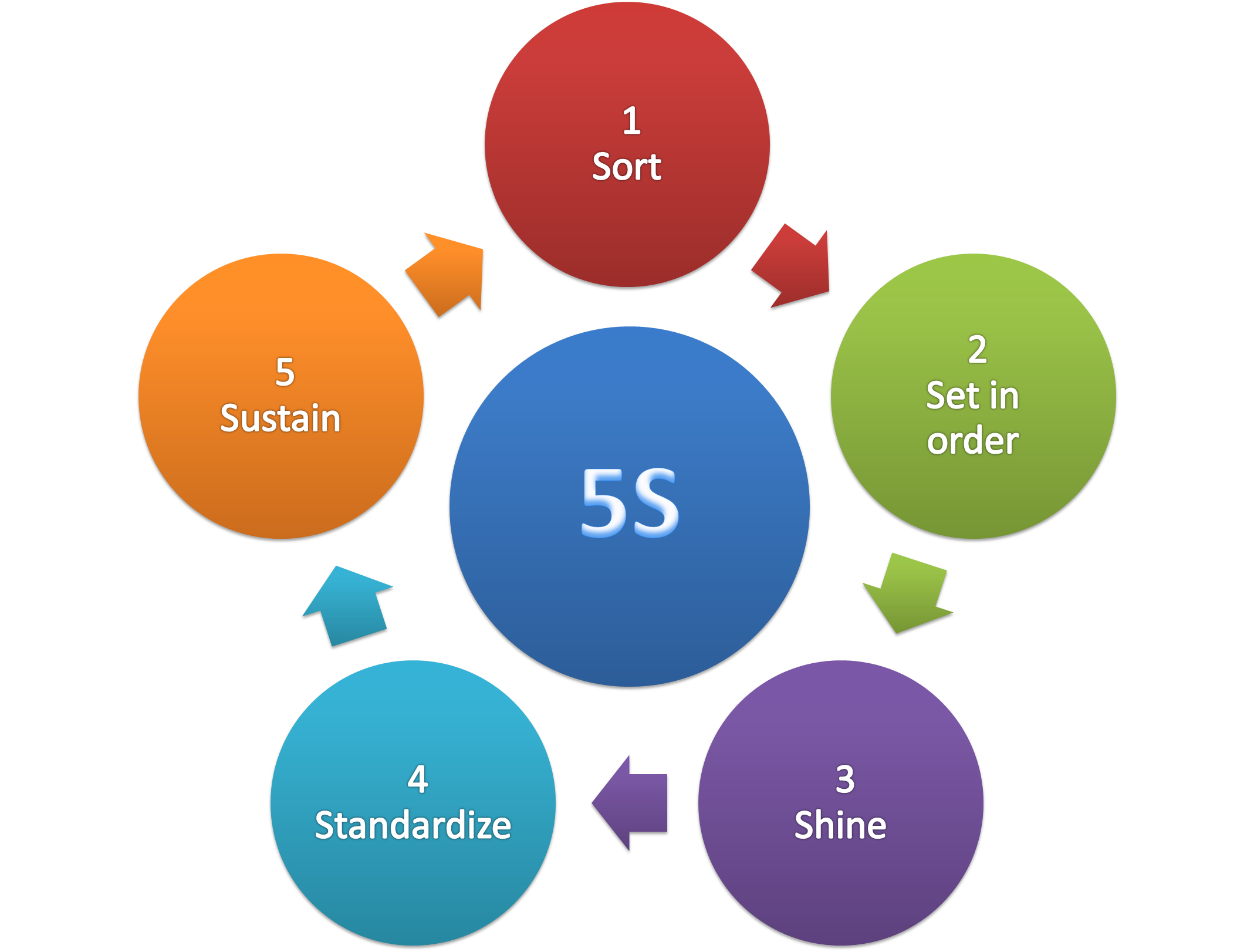

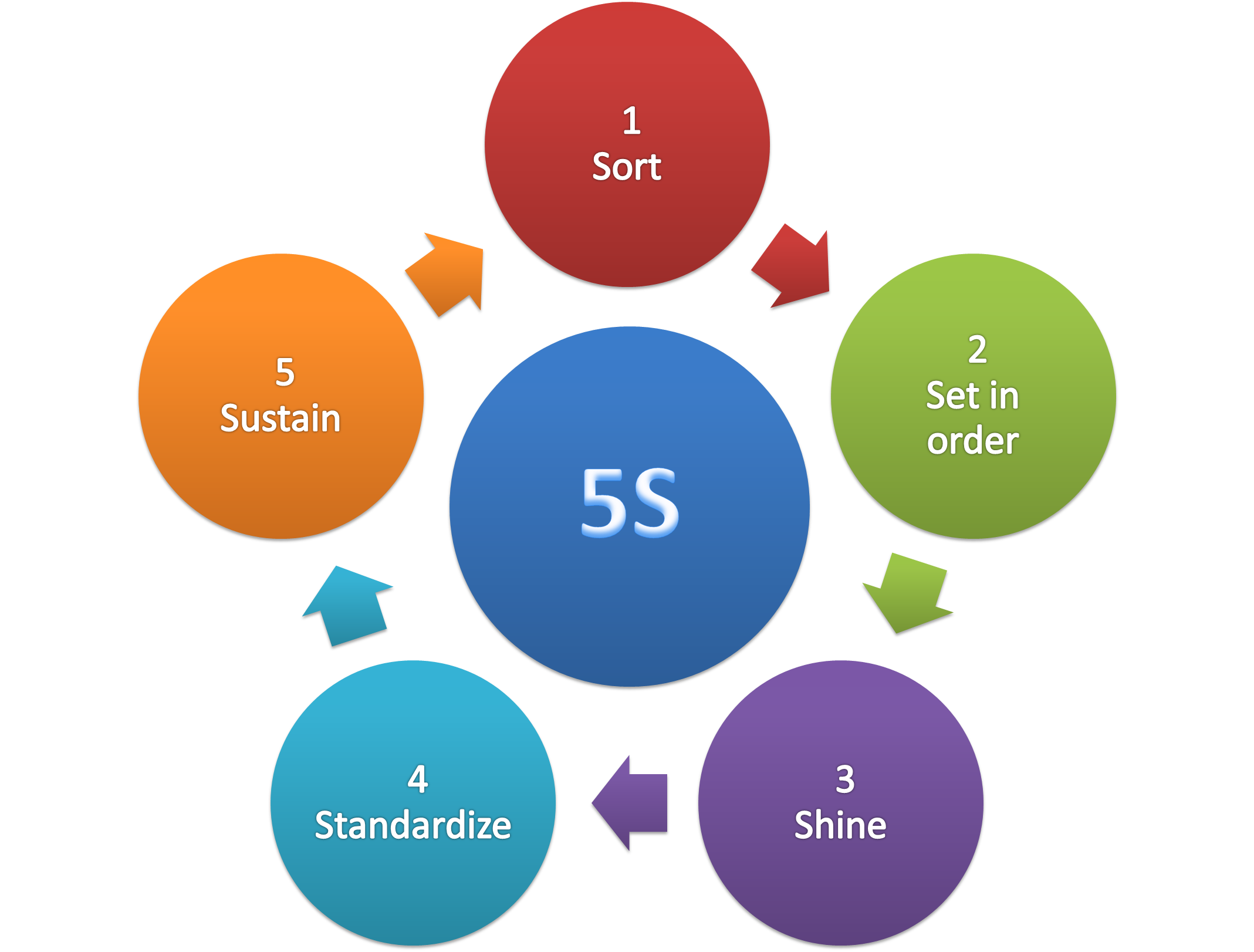

This is part 2 of our series on 5S implementation. In part one, we talked about getting everyone on the same page about the implementation alongside...

This is our third and final installment of our series on 5S implementation. If you haven't already, take the time to read it from the beginning starting with part 1 and continue with part 2 for a fast, efficient and (most importantly) successful implementation of 5S, a lean-light business methodology.

The short answer to this question is that there is no right or wrong answer. It all depends on your business’ ability. This includes the size of your workforce, finances and the amount of time you have available to work on it. Of course, the goal is to be as thorough as possible when going through the Shine and Standardize phases of the implementation because each step builds from the previous one. So, if one step isn’t done correctly or isn’t properly completed, every step that comes after it will be affected which could ultimately make the implementation unsuccessful.

Each step in the 5S method should be viewed as a phase. The good thing about the shine and standardize phases is that they are the only two that don’t necessarily have to be “complete” because they are ongoing processes. It is because of this that there is debate on what is a good stopping point for the initial implementation.

As I stated earlier, it really depends on the individual company: how much work needs to be done, and what the company hopes to gain with the implementation. For example, if the last time your warehouse was cleaned was over five years ago, you are going to want to take your time in the shine phase because there is a greater need. At the very least, you are going to want to get the biggest, toughest parts of shine and standardize out of the way during the to help with the implementation.

You might be wondering what should be done if your company has already recently done one of the steps in 5S. Do they re-do that step or just skip it entirely? I’m glad you asked because neither of those options will help the implementation. In that situation, it is ideal to use that step to improve upon your previous work. For instance, if your company already has a policy for standardization in place, the standardize step of your 5S implementation should involve your team re-evaluating your policy to see if it is still in tune with the new improvements being made.

When deciding what to do in the shine and standardize phases of the initial 5S implementation, you should start with what’s most important. Make a list of all the actions that need to be taken for each step then prioritize them based on what is most vital to the success of your implementation goals.This is especially important if you have multiple locations and/or facilities that may not have the same needs or capabilities while still enforcing certain standards.

Some general tips to follow are to remember to take each phase of the implementation seriously and don’t “half do” a step just to save time because it could end up making the whole implementation process ineffective. The last tip we will give you for a 5S implementation is to have a solid ERP solution to support and record your process. For this kind of process, you will want a solution that has inventory management, gathers data/analytics on operations (to measure results) and scheduling to track time spent on the implementation. Now that you are all set with what you need to know to begin a 5S implementation, you can be confident of its success that could result in 69% faster growth and up to 45% improved productivity.

Clients First is an expert at implementing Acumatica, Dynamics 365 and Dynamics AX (which also made it into the leader quadrant). Contact our sales team today by calling 800.331.8382 or emailing info@clientsfirst-tx.com. Clients First implements and supports clients across the U.S.A. and in 11 countries. Our team of professionals are ready to help implement the best finance and operations solutions for manufacturers, distributors, project-based manufacturers, MRO (maintenance, repair and overhaul), and professional services.

Source: Industry Week

This is part 2 of our series on 5S implementation. In part one, we talked about getting everyone on the same page about the implementation alongside...

1 min read

ERP Implementation Strategies for a Successful ERP Upgrade If you are a small to mid-sized business (SMB) and growing, you will eventually need an...

1 min read

Why is a Post-ERP Implementation Strategy Important? At Mantralogix, our ERP consultants spend a lot of time discussing ERP implementation...