Dynamics NAV Warehouse Inventory Flow: Step Up Your Performance

Companies who struggle with managing warehouse inventory turn to Microsoft Dynamics NAV to improve their warehouse inventory flow. In this blog we...

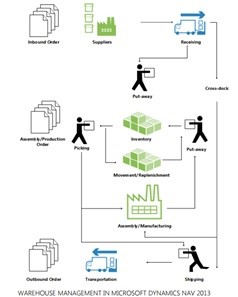

The supply chain in Microsoft Dynamics NAV 2013 extends into the warehouse. Through the ERP's warehouse management functionality, users can manage items down to BIN level.

i) Easily set up and maintain your bins by defining both the layout of your warehouse and dimensions of your shelves, columns and racks.

ii) Pick items from a bin according to a put-away template.

iii) Receive and put away items in a bin.

iv) Pick items based on the bin ranking and zone.

v) Setup and maintain your planning parameters by characteristics and limitations of each bin.

vi) Move items between bins using a report for optimizing the space usage.

The WMS in NAV 2013 is integrated with the rest of your in-house systems to streamline operations, speed order fulfillment and reduce costs. The WMS can help organizations manage space and goods more effectively and reduce costs and waste.

Employees in your warehouse can save time performing physical inventories counts or locating items thanks to access to real-time, accurate inventory data. At the same time, your sales reps can keep tabs on stock availability while buyers can ensure stock levels are optimum while minimizing carrying costs.

Put-away/direct pick processes, support for Automated Data Collection Systems (ADCS) and other item tracking options- including first out/first expired handling- can significantly improve your warehouse management.

You can choose the level of sophistication you need with confidence that the WMS can scale as your business grows. Apart from this, the software will easily adapt to new processes, technologies, volumes or products.

You can automatically update pack status or pick and process to ensure orders are accurately fulfilled in a timely manner. Another benefit is faster responses to status inquiries.

WMS helps to reduce bottlenecks and multiple handling with directed put-away and pick. You can also input material handling information directly from the warehouse to reduce redundant data handling and increase efficiency.

You can set up criteria to guide the most efficient bin quantities, put-away locations and pick patterns. The functionality enables users to pick items per order or to stage, save and consolidate effort by taking advantage of cross-dock opportunities.

Integration between Assembly Management, Service Management, and Manufacturing and Warehouse Management has been enhanced to deliver paramount benefits to both partners and customers.

Through better utilization and enhanced integration of warehouse functionality, the WMS gives organizations confidence in processes and delivers more accurate inventory. The result is that organizations are left with more finances for other investments.

Rather than working on integrations, partners can focus their efforts and resources on other important activities that generate additional revenues, and realize faster implementations.

One important addition in NAV 2013 WMS is Inventory Movement. This module has been added to the non-WMS locations and is used to move items between different departments, such as services and production departments, where items are posted as either shipment, consumption or others.

With Inventory movements, warehouse operations can be streamlined by giving employees a more accurate and easier way to register actual movement of materials and items without having to do a journal posting. Companies can gain insight into stock levels and inventory’s location in the warehouse. With this information, organizations will have better information on which inventory to order based on their availability in stock.

i) Inventory movements can be made without a source document through an internal movement.

ii) Inventory movements cannot be posted. They can only be registered as warehouse entries.

iii) Each inventory movement includes both a put-away and pick, which are represented by a place line and a take line.

When an item is assembled in a sales order right before shipping, an inventory movement is instantaneously created to move the item to the assembly area. This is usually the case when the inventory pick for the assemble-to-order item is recorded as shipped, assembled or sold.

Companies who struggle with managing warehouse inventory turn to Microsoft Dynamics NAV to improve their warehouse inventory flow. In this blog we...

Panatrack and V-Technologies StarShip shipping software offer a fully-integrated pick, pack, and ship solution for Microsoft Dynamics GP. Learn how ...

Microsoft Dynamics NAV: Warehouse Management Microsoft Dynamics NAV is the quintessential solution for complete enterprise management of your entire...